- Technical Data

- Areas Of Application

- Materials

-

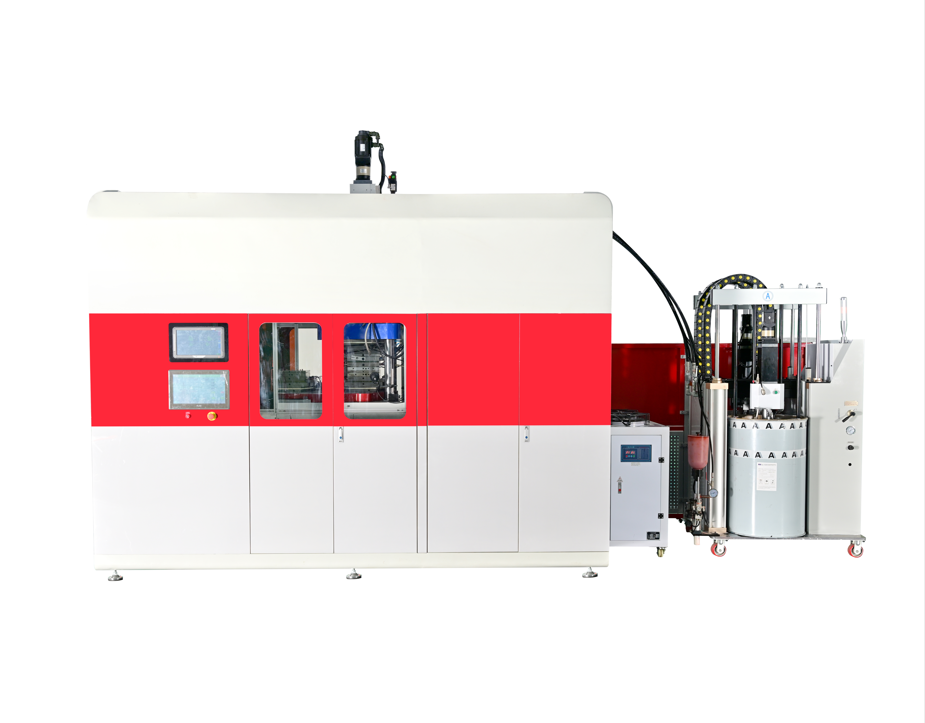

- Products Name: LSR material making machine

Name

Unit

Parameter

Dosing pressure

MPa

0-40

Viscosity

pa.s

0-35000000

Max. injection speed

L/min

0-3

Capacity

L

200L/20L

Drum/Pail qty

pcs

2

Voltage

380V/50HZ

Air pressure

Kgf/cm2

6

Maximum air consuming

ft^3/min

5

Hydraulic pressure

mpa

0-14

Batching system

L/H

170

Power system

base material

servo hydraulic

Batching material

Servo driven ball screw structure

auxiliary material

Pneumatic

Overall dimensions

6500(L)x6000(W)x2250(H)

Pipe

Base material

m

1 inch-2 inch resin pipe

Batching material

1 inch resin pipe

Auxiliary material

1/2 inch resin pipe

Automatic lifting device for output (servo screw structure)

m

0-1.1

Mixing unit(with cooling device)

Stainless steel

Chiller

P

0.5

Filter unit

mm

Single board dual station screen changer, filter diameter 150

Vacuum automatic defoaming device

mpa

-0.098mpa

Cover area( in theory)

mm

6500mmX6000mm

Production capacity(in theory)

( production capacity varies with base material viscosity)

T/h

A component 4 ton/24 hour( in theory)

Buyer's base material at 3500 pa. s,

Actual Capacity:≥ 3 ton /24hours

B component 4 ton/ 24 hours(in theory)

Buyer's base material at 3500 pa. s,

Actual Capacity:≥ 3 ton /24hours

Key words:- silicone injection machine

-

liquid silicone rubber

LSR material

Related Products