- Technical Data

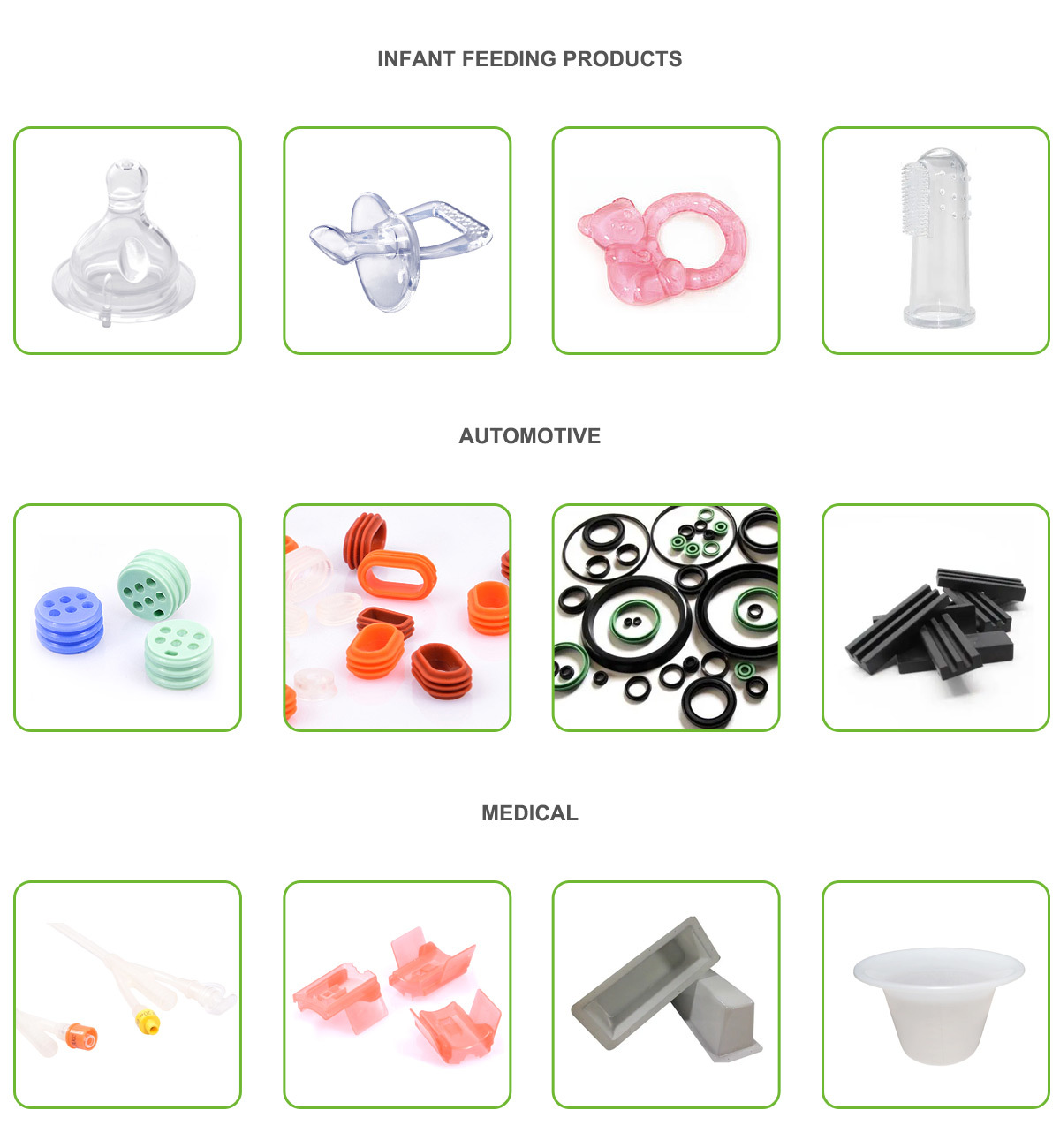

- Areas Of Application

- Materials

-

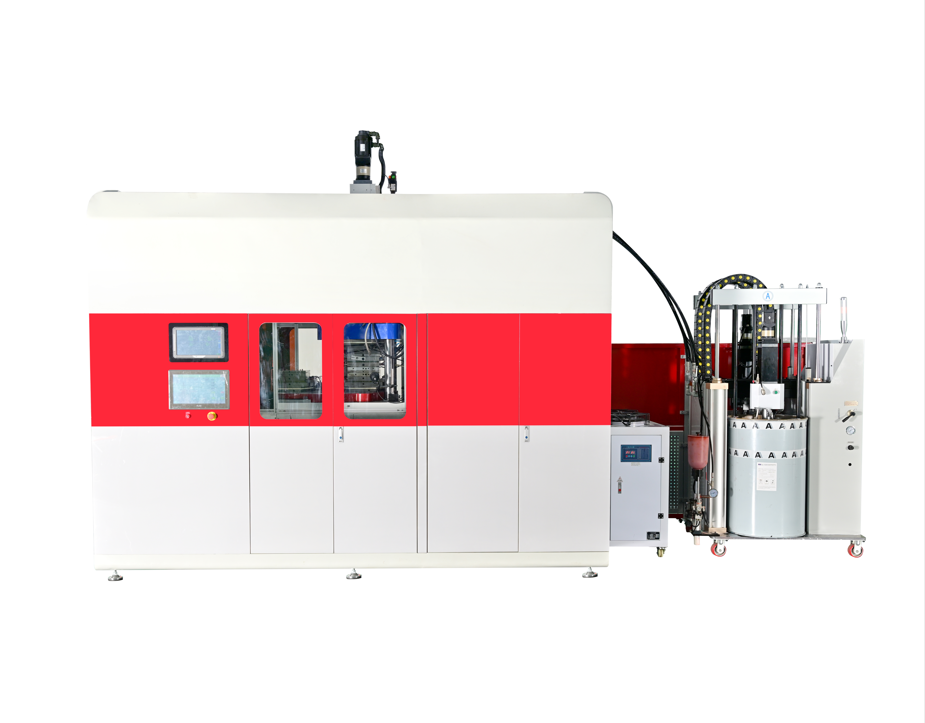

- Products Name: LSR dosing machine D516

Products Description:

1. A component and B component is balanced manually. 2. High efficiency, energy saving. 3. Pigment adding is stable, no flow line.Parameter of Host machine

No.

Main parameter

Type

Unit

Parameter

1

Machine Model

upgrade

set

D516

2

Material viscosity

Rotary viscosity

mpa.s

0-3000000

3

Static mixer

G3/4

RC

1pc

4

Material package

Standard LSR package

L

200L/20L

5

Drum Qty

--

pcs

2

6

Mixing ratio

--

--

1:1

7

Mixing precision

Manual balanced

--

2%

8

Air supply

Pneumatic

MPa

0.6-0.8

9

AB pumping pressure(outlet of pump body)

Servo hydraulic

MPa

0-10

10

Output speed in theory (outlet of machine)

Servo motor

L/min

0-2

11

Pipe

Resin pipe

--

3/4 inch

12

Rated total power

Hydraulic station(Three-phase asynchronous motor)

KW

2.2

13

Maximum air consuming

--

Ft^3/min

5

14

Weight

-

t

1.0

15

Machine dimension

L×W×H

--

mm

1190x1200x1700

Parameter of injection station

No.

Main parameter

Type

Unit

Parameter

1

Model

Upgraded

set

Hydraulic injection station

2

Injection pressure(outlet of injection station)

Hydraulic servo

MPa

0-60

3

Storage volume(injection station)

Hydraulic servo

g

0-800(A+B)

4

Rated total power

Hydraulic station(servo motor)

KW

7.5

5

Injection speed in theory (outlet of injection station)

Servo hydraulic

L/min

0-3

6

Injection pipe

Resin pipe

--

3/4 inch

7

Maximum air consuming

--

Ft^3/min

5

8

weight

--

t

0.4

9

dimension (L×W×H)

--

mm

830x600x1500

Key words:- D516

-

-

liquid silicone rubber

D516

Related Products