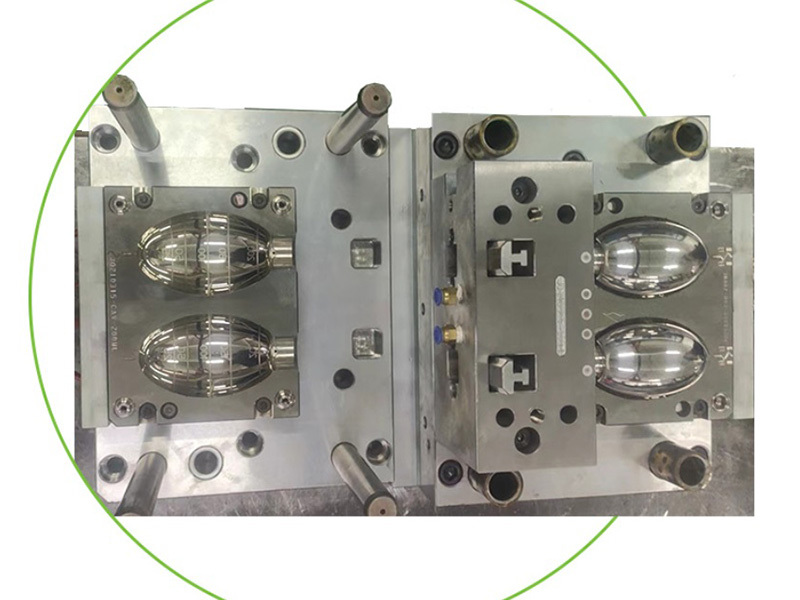

- Technical Data

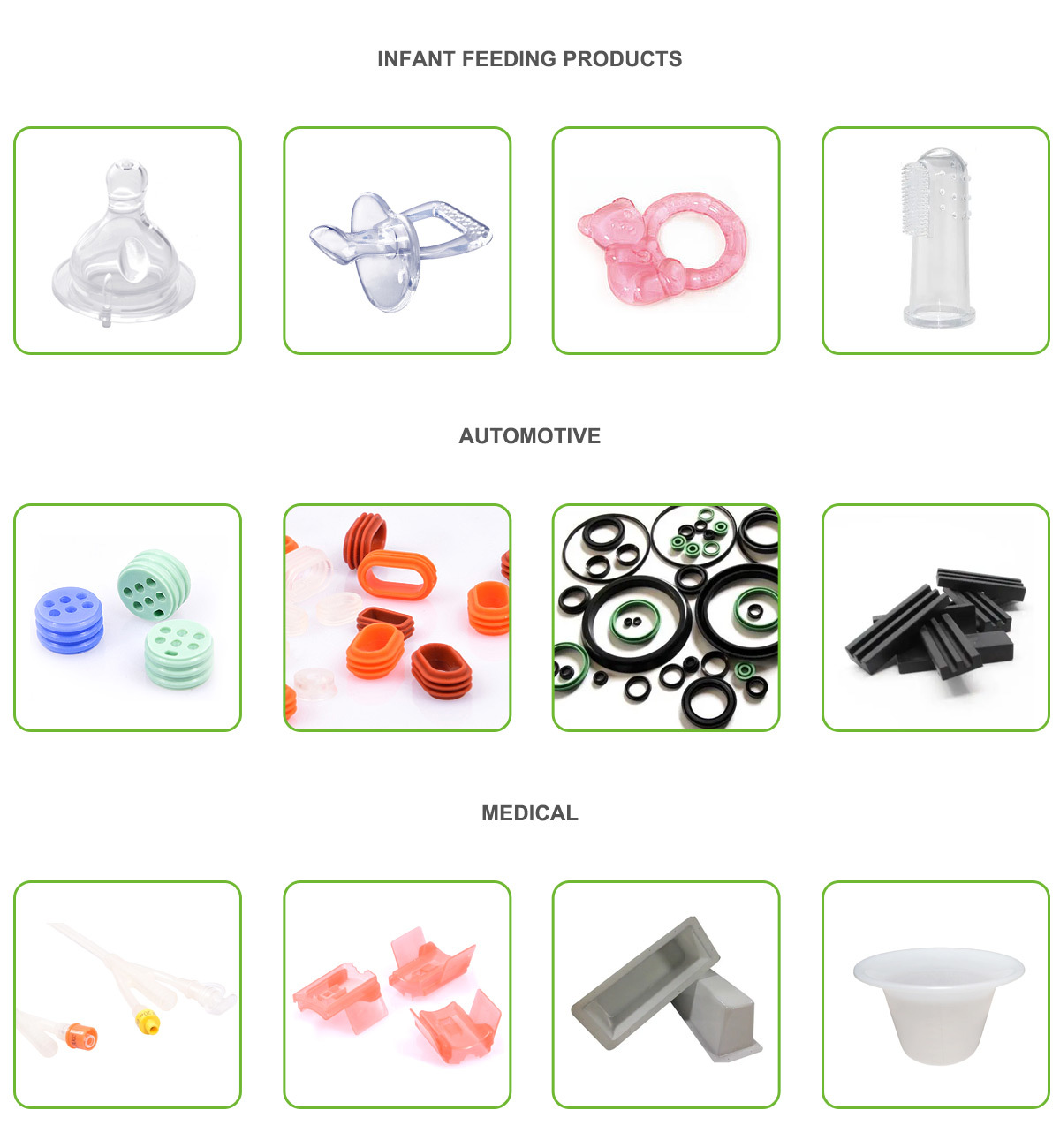

- Areas Of Application

- Materials

-

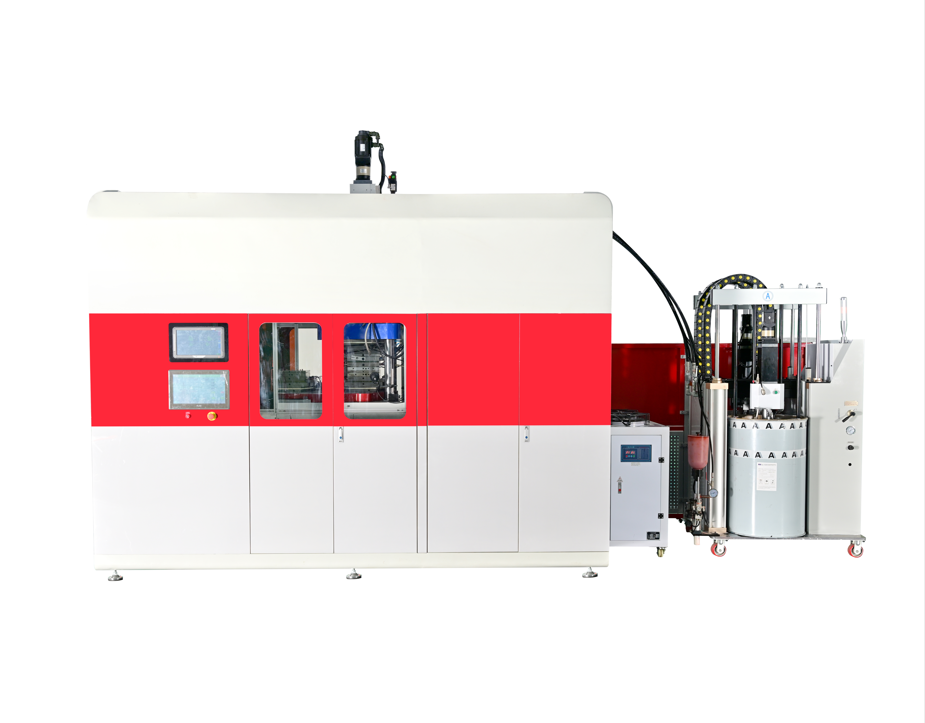

- Products Name: LSR dosing machine H930

Products Description:

1.Electric machine. 2.A component and B component is balanced automatically. 3.Pigment is added by servo motorNo.

Main parameter

Type

Unit

Parameter

1

Machine Model

upgrade

set

H930

2

Material viscosity

Rotary viscosity

mpa.s

0-3000000

3

Static mixer

G1/2

RC

1pc

4

Material package

Standard LSR package

20L

5

Material Qty

--

pcs

2

6

Mixing ratio

--

--

1:1

7

Mixing precision

Automatically balanced

--

0.5%

8

Air pressure(follower plate lifting)

Pneumatic

MPa

20L pail 0.1-0.2

200L drum 0.6-0.7

9

AB pumping pressure(outlet of pump body)

Electric

MPa

0-30

10

Output speed in theory(outlet of static mixer)

Electric

L/min

0-2

11

Pipe

Resin pipe

--

3/4 inch

12

Material LSR passed

Follower plate

--

Aluminum alloy

Pump body

--

45# steel plating

Conveying pipe

--

Resin pipe

13

Rated total power

Pneumatic

KW

0.3

14

Maximum air consuming

--

Ft^3/min

5

15

Weight

-

t

0.7

16

Host machine dimension

--

mm

720(L)x720(W)x1906(H)

Key words:- LSR dosing machine

- LSR injection molding machine

-

-

liquid silicone rubber

H930

Related Products